Car Design Review X: The future of texture

Architexture’s EMEA design manager, Marion Jaillant, explains why the future of car interior textures has to go beyond just touch and focus on the whole experience

Where do you see the future of texture within car interiors?

My feeling is that traditionally, textures were used to cover and mask the defect of the moulding process. Then they slowly became an artistic expression to enhance the branding of a company. But now I think it’s moving towards user experience. I feel those are the three big stages.

What research has led you to that conclusion?

Last year I went back to study for a Masters degree in Visibility Design and Innovation and to explore the relationship between texture and user experience. My final project worked with users of prosthetics to see how the texture of a prosthetic limb could make the user have a better connection with it. Because sometimes people give up on their prosthetics, because they feel so ‘alien’.

That’s fascinating. What did you explore?

My project was about how texture can create emotions and if you’re involved in designing your own texture, how you can actually feel like it’s part of you. That led me coming back to Standex and wanting to explore this user experience topic and having conversations with our carmakers: “Have you ever considered that texture could make people feel a certain way?” Mobility in general is changing with autonomous vehicles to give better access to disabled people and maybe attract a younger demographic. So what we would like to explore as a company, is how texture can be used not only for functional or aesthetic purposes, but how it can make people feel.

You mentioned a traumatic personal experience that helped you understand this subject better? Could you explain more?

I was 20 years old and finishing my degree when I had a stroke. After two surgeries I lost my eyesight and it took about four months to progressively recover. After each surgery, I had about 10 days in hospital so the doctors taught me to walk around without my eyesight. I had to learn to walk the corridors and move around my room just by feeling and touching. It made me realise how awful to feel the texture of the walls and even the hand rails were, absolutely horrible.

“We want to explore how texture can be used not only for functional or aesthetic purposes, but how it can make people feel”

In what ways?

They were made of cheap plastic and very smooth, nothing comforting. That’s when I started to think, “design could make such a big difference.” And that’s why more recently I decided to go back to study to see how design, and more specifically texture, could improve the life of people with disabilities. It’s a topic ignored by so many people. In the UK around 20% of people live with a disability and worldwide it is 15%. That’s too big a group to be disregarded from serious design consideration.

How has that experience made you want to design differently?

It’s such an under-explored area, which means there are a lot of opportunities to research and develop. Things that actually mean something and make a difference to people’s lives. When we talk about design, it’s all about cost and functionality. But the conversation we’re now starting to have with customers is more about actually designing for people, rather than designing for cars.

Do you think carmakers are more receptive to this idea now?

Definitely, and we’ve even seen some customer teams renamed, instead of being called colour, material and finish, they’re now called colour, materials and experience.

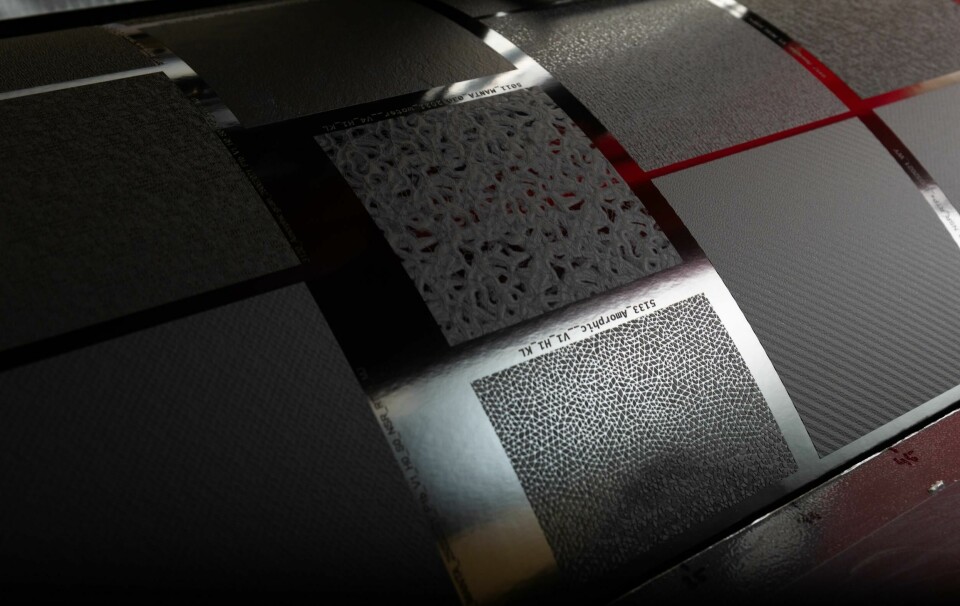

Are your carmaker clients using Architexture to create bespoke textures to match their brand philosophy? Or are they still just picking ‘readymade’ designs ‘off the shelf’?

I think it’s a bit of both. When we talk to all the different carmakers, there are the big ideas, like sustainability, recycled materials and all of that and these things affect the aesthetics of some of our grains. But I also see some brands with a strong graphic identity wanting to reinforce this by using the grain we help design for them.

What styles of texture are you are getting asked to develop?

People want to be inspired by nature. So a lot of the trends we are receiving are moving away from animal grains to more cellular shapes and patterns. The trend has become a bit more ‘grainless’, if anything, people just want to use and show the raw material.

Doesn’t that partly put you out of job?

That’s why we want to explore the user experience and offer something else, even if it’s almost an invisible grain, it could make a difference. We just have to create something that’s well-integrated with these new materials because people want to display those recycled effects. We would love to create a new collection of grains that work well with those materials and we have people in UK, China, US, Portugal, Germany, Italy and France who can help create them.

“We believe this new tool will gain traction on soft trim designs and become a game-changer”

Are you experimenting with AI within your work?

We are, partly because of wanting to reduce weight in electric vehicles. Carmakers are trying to take the thickness out of their plastic parts and so we’ve had some requests which we’re working on. Normally you’d put ribs in to give extra support to these parts. But what we’re trying to do is see if a texture can give you that extra strength on the B surface, and reduce weight, while maintaining the same strength.

What other texture trends do you see emerging soon?

One huge movement is personalisation. There’s a thought that in a few years, when a customer finishes a lease and the car goes back to the dealer, they will be able to sell it more quickly if there is some interchangeability of parts. So a simplification, at least in the cockpit, will allow personalisation to be done easier.

There could be simple bits that could be dropped in, with different colours, textures and materials to make it the new customer’s car, rather than the previous owner’s. It could be done at the dealer and all they would have to do is wrap something, like a Polyurethane (PU) skin or similar, over the dashboard. Carmakers are trying to simplify those areas so that things can be interchangeable.

And what new tech from your firm are you most excited about?

We have a new machine with a 1.65-metre long drum and two-metre circumference able to create 3D texture using special resin poured into the machine and then fired on to a texture-less black vinyl via multiple passes. It builds in a generative 3D-printed way and allows the texture designs of our customers to be quickly created and physically verified without a metal engraving process, which is much more costly and time-consuming. We believe this new tool will gain traction on soft trim designs and become a game-changer.