Collaboration central to materials innovation, says Ultrafabrics

Ultrafabrics aims to redefine what it means to be an automotive supplier, positioning itself as a development partner with cross-industry expertise

Gone are the days where suppliers sit at arm’s length with an array of generic products. Now more than ever they are working side-by-side with their customers, deeply embedded in the development process and engaging in a thoughtful exchange of skills and processes.

In the world of automotive CMF, industry relationships are perhaps even closer as carmakers look to create sustainable yet engaging interiors. In an ideal world, the materials supplier would not only provide a sounding board for the OEM, but actively explore new areas and bring fresh solutions to the table. With creativity and innovation pushed to new levels – backed by newfound knowledge – the resulting product will undoubtedly better meet the needs of the end user.

At Ultrafabrics, the nature of collaboration extends even further, not only with the OEM but across its vast network of contacts. Numerous divisions work alongside experts in niche fields to stay at the forefront of what is possible, and to understand where lofty visions could in fact be brought into the mainstream.

“We’re redefining what it means to be an automotive supplier,” the company says, “and our expertise goes far beyond fabric. We’re a forward-thinking partner, delivering innovative, multi-industry insights and advanced material solutions that inspire CMF teams and transform car interiors.”

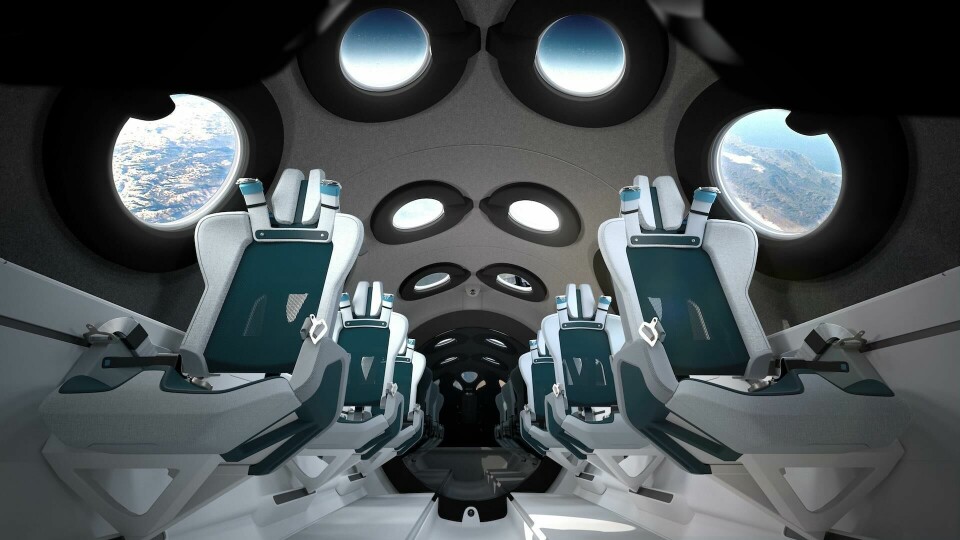

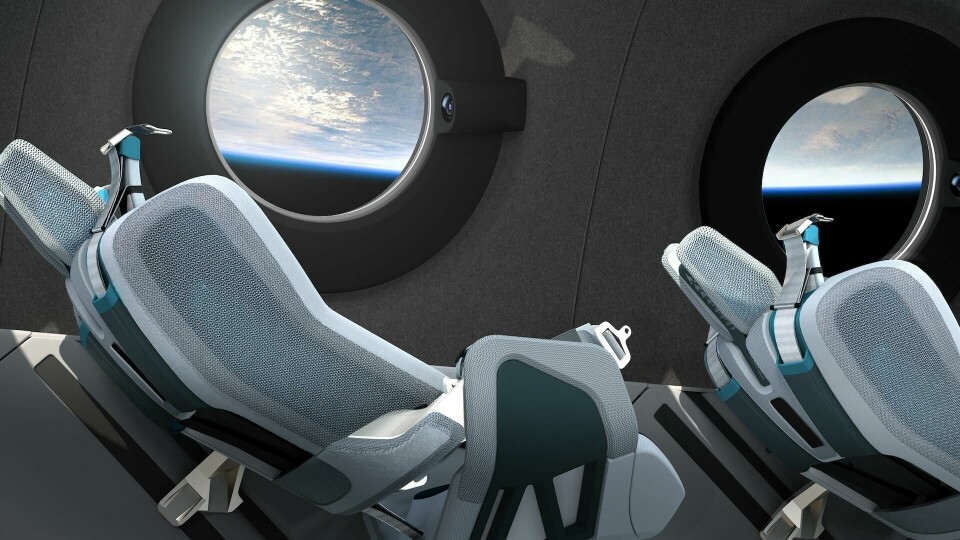

Indeed, those partnerships go beyond automotive to tap other adjacent industries like aviation, aerospace, marine, healthcare, hospitality, and furniture. Notable partnerships include those with brands like Fitbit, Virgin Galactic, Herman Miller, Airstream and JLR. This strategy has already resulted in breakthroughs, from new UV-resistant fabrics for marine exteriors to bio-based materials for aviation.

As a sponsor of CDN’s upcoming livestream on the future of German car design, the team at Ultrafabrics notes that European OEMs have been actively exploring alternatives to both conventional and PU leather in particular.

“We’re excited to see an increasing recognition of the need for new material spaces,” observes Kimberley Harrington, automotive advanced sales manager at Ultrafabrics. “German OEMs are known for their engineering excellence, but their interiors have traditionally been leather and achromatic. As we begin working with more German customers, we’re seeing parallels with other Central European OEM requests, such as a focus on bio content, sustainability and flat, technical grains.” Harrington adds that there is also growing interest in “soft, neoprene-like materials and new grain directions, moving away from traditional leather-based options.”

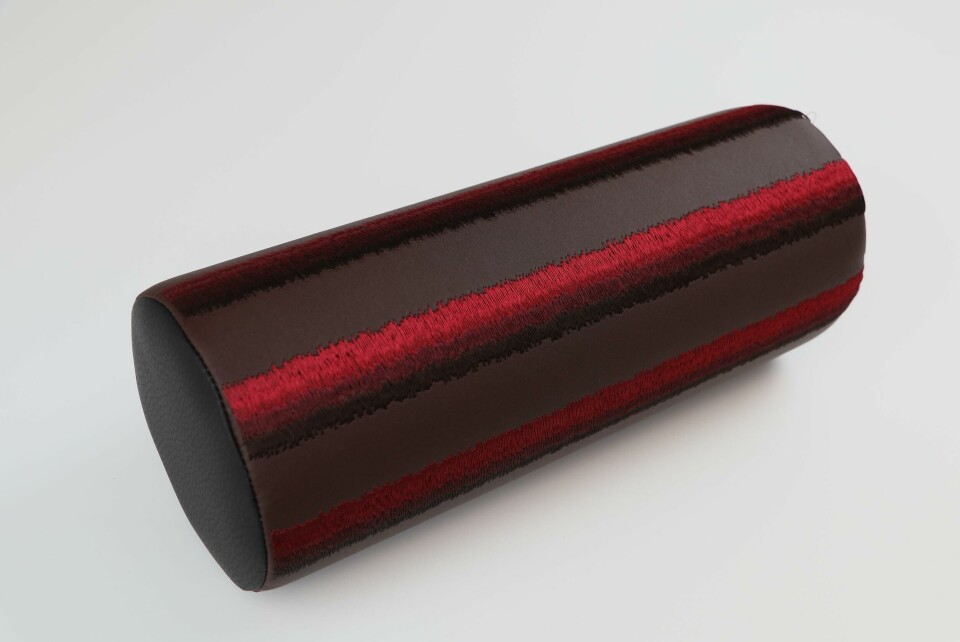

Indeed, the team is deeply invested in exploring material capabilities and has given particular attention to secondary surface finishes. Over the last five years or so, Ultrafabrics has been working with UK-headquartered Embroidery Design Solutions (EDS) to explore all manner of new embroidery, quilting, cut, sew, perforation and laser etching techniques, among others.

The collaboration has been fruitful for both sides and Catherine Johnson, founder of EDS, explains that the right partnership can align shared values and standards while pushing creative boundaries: “We aim to ignite and inspire automotive designers with visionary creative concepts and this collaboration gives us the perfect platform to illustrate this.”

What sets us apart is our focus on the “why”

As might be expected of a premium materials specialist, colour trends are also a key area of focus. Ultrafabrics’ annual Color Impact Report – which investigates the influence of colour and texture on design – draws on the knowledge of experts such as Cristin Richard, House of RAW (Research and Worldview), who has worked closely with the product development team for years.

Richard notes that it is important to “connect the dots” between different industries in order to gain a comprehensive understanding of consumer needs (and desires). “The report is developed through a deep analysis of the times, fuelled by cumulative knowledge and a discerning eye,” explains Richard. “This maintains a critical human element in the design process that cannot be replaced or replicated by AI.”

Johnson of EDS adds: “Central to the innovative work, we work with Ultrafabrics on the annual Color Impact Report, realising these concepts into innovative secondary finishes that push boundaries in design and spark creativity. It is this body of work that really excites and aligns this unique partnership, and in turn the client base it serves. Together, through the Color Impact Report we have a truly aspirational narrative to tell.”

On the product development front, sustainability has become a core tenet. In the realm of CMF where materials selection is under greater scrutiny – and directly interfaces with the end user – it is crucial to find a solution which not only exceeds black-and-white content targets but also the more subjective issue of how a customer perceives the material.

“Sustainability is at the core of Ultrafabrics’ mission. We want to provide sustainability without sacrifice,” say the product development team. “While not every innovation succeeds, we view these challenges as opportunities to innovate further, from addressing local sourcing issues around promising coffee-based dyes, to success stories with increased bio-material content which is now reaching all the industries we serve.”

To maximise the chances that innovation does hit market, the commercial team fosters relationships with carmakers that want to stand out. While nothing is ever left to chance, there is a degree of instinct that comes into play, a skill that is honed from years of experience in the materials arena.

“With deep automotive textile manufacturing backgrounds and experience at OEMs, our team naturally anticipates our customers’ needs and understands automotive processes,” explains Harrington. “What sets us apart is our focus on the ‘why,’ providing materials that are beautiful, sustainable and high-performing without compromise. We go beyond material exploration, collaborating with talented partners and helping clients approach projects with varying grades and budgets.”

Harrington sums things up nicely, describing the strategy to be “a new type of automotive supplier” as a combination of American customer service energy with the Japanese pursuit of perfection. As she puts it: “Collaboration with us is truly unique.”