CMF experts CNT Factory pick out some groundbreaking projects and materials, including work from BMW and Freitag

BMW lightweight, sustainable seat structure

The seat design was enhanced throughout the development process by extensive lifecycle evaluations. Its CO2 footprint is 90% lower than a BMW M carbon bucket seat thanks to the use of ultra-light, robotically wound fibre composites and polymers derived from algae. Lower module complexity and the use of materials grouped by type make it easier to recycle the seat at the end of its lifecycle. Additive manufacturing made it possible to eliminate support structures and chemical post-treatment.

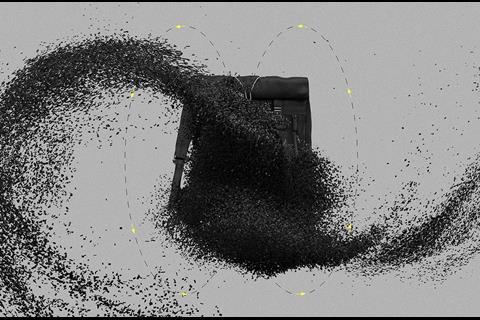

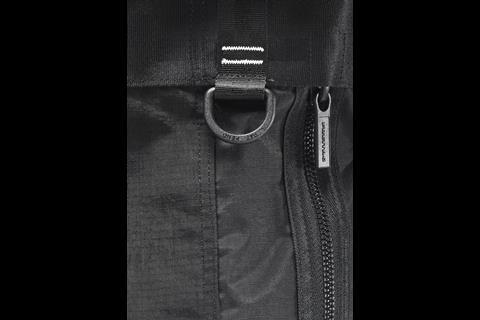

Mono[PA6] Backpack

The new Mono[PA6] Backpack from Freitag is constructed entirely of one material, designed to maximise recyclability. Polyamide 6, or nylon as it is more commonly known, is used for all 17 different components, from the cables and buckles to the zippers and water repellent skin. Customers can return the backpack to Freitag at the end of use for it to be fully recycled.

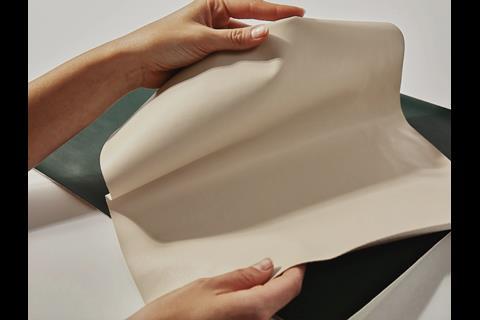

Banbū leather altenative

Banbū Leather is a next-generation leather alternative that is 83% plant-based, non-toxic, and biodegradable in a landfill. Known for its strength and resilience, bamboo is one of the fastest growing plants on the planet, and can be harvested without destroying root systems. By combining the bamboo fibres with plant-based, durable topcoat, the company estimates a carbon emission savings of five times when compared to traditional cow leather.

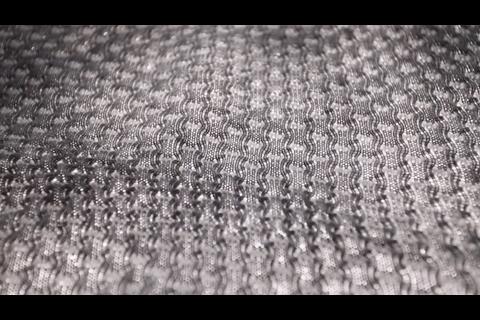

Tyre chair: Recycled rubber and raw aesthetics

Commissioned by Axoo Agency and Hyosung Advanced Materials, the Tyre Chair by Wendy Andreu takes inspiration from the tyre cord manufacturing process. The composition includes a fabric covering blended with Lyocell tyre cords, cotton, silicone, foam, and a zip. By combining these materials, the artist created a unique, high-quality textile. The design merges functionality with the aesthetics of tyre cords, showcasing a creative approach to material use and sustainable design.

Adaptive fit

The “Adaptive Fit” trend is pushing boundaries in material innovation and manufacturing processes. Spray-ON shoes use a liquid polymer that solidifies on contact, forming a seamless, custom fit directly on the foot. This process merges material application and fabrication, eliminating waste and offering bespoke comfort. The 4D knit dress from MIT utilises advanced knitting techniques with smart materials that respond to body movement and heat, dynamically adjusting the garment’s structure. This approach in CMF design emphasises adaptive, user-centric products, and results in highly personalised and responsive fashion items.

No comments yet