PARTNER CONTENT

This content was paid for by Peer Group and produced in partnership with Car Design News

Tucked away in the anonymity of the Cambridgeshire countryside is a championship-winning facility that promises to use its racing pedigree for the next generation of electric vehicles (EVs)

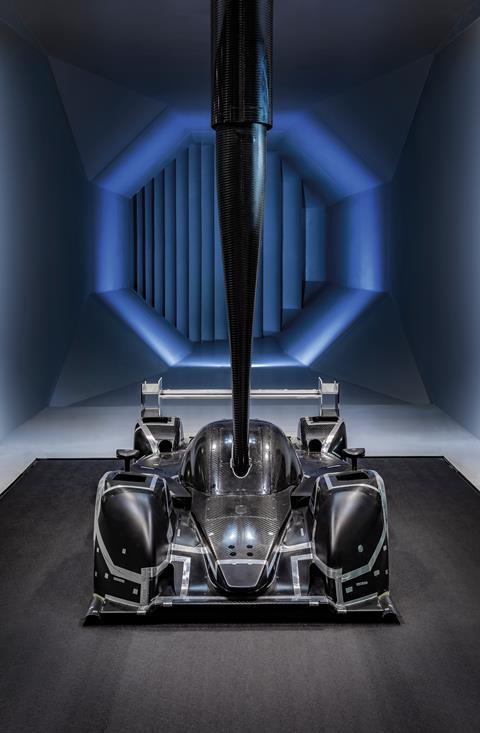

The Lola wind tunnel is a state-of-the-art facility that has supported top motor racing teams, car brands and a host of other vehicle manufacturers. The site in its current form was established by Lola Cars, which for decades can be attributed to a host of historic wins and iconic drivers such as John Surtees and Nigel Mansell.

Now, the facility is up for sale and although its pedigree for motorsport applications remains, there is perhaps a greater opportunity for established carmakers to refine the next generation of EVs destined for public roads.

Aerodynamics is an incredibly complex field and measuring it is even more so. Wind tunnels are feats of engineering in themselves and are calibrated to the highest sensitivity, measuring how cars glide through the air and their stability at high speed and through corners. The Lola wind tunnel’s six-component balance system paired with Cosworth’s Diablo software can accurately and reliably gauge all of this.

Computational fluid dynamics (CFD) is of course the de facto means of developing an aerodynamic vehicle in the first instance, enabling teams to trial the performance of a car and make refinements in real time. This is all well and good, but just as a hard model is used to validate a 3D model, a wind tunnel is vital to prove that theoretical drag coefficient in the real world.

The difference between performing in a simulation and on a rolling wind tunnel can be surprising. Just ask any F1 team: wind tunnels are deemed so useful that there is a limit to how long they can be used for fine tuning. Imagine having unlimited, on-site access.

Indeed, wind tunnels are not always available and spots can be booked for weeks at a time. Not every site is conveniently located, either, perhaps requiring models to be built and shipped in from afar. In theory, having a private facility close by would be ideal.

This represents incredible value in relation to building and developing a new wind tunnel

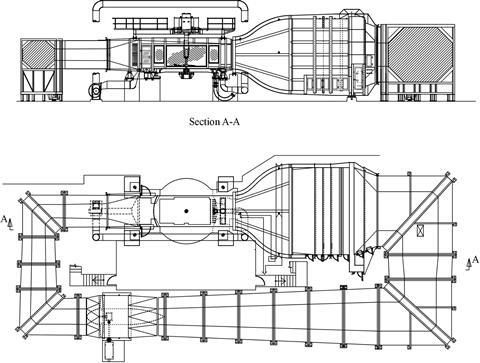

Good job then, that the Lola wind tunnel can be disassembled and shipped anywhere around the world with the help of specialist companies like Aiolos Engineering. And this is not theoretical – the modular steel construction has been relocated before. This makes the proposition all the more enticing not only for those in the UK but globally. And with workshops and associated machinery used to create prototypes on site, it is a turn-key solution for any design studio to bring a wind tunnel into the fold. Not to mention the element of privacy that comes from owning a facility outright – safeguarding the all important metrics and eliminating any chance for competitiors to copy your answers.

“For race teams, OEMs and businesses providing motorsport and automotive engineering services, this opportunity represents incredible value in relation to the cost of building and developing a new wind tunnel,” says Howard Dawson, managing director of the wind tunnel’s current owner, Peer Group. They estimate that a new tunnel to a similar specification would cost 15 to 20 times the asking price of the Lola test facility. “The 2024 major upgrade to the tunnel’s systems now provides for pre-programmed automated testing,” Dawson adds, “with full model motion control and easy integration with the very latest sensor technologies.”

Although EVs are improving at a rapid pace, there is no shirking the fact that range and charging efficiency remain key challenges. Less drag means the same range can be achieved with a smaller battery pack. Smaller batteries charge faster, and weigh less, further optimising the equation.

Batteries are not cheap, either, and even a small cost saving can be enormous when multiplied over a mass-produced line-up. Crucially, the Lola site has been used not only for racing and passenger cars, but also heavy-duty commercial vehicles and motorcyles – the potential applications are vast.

The current owners of the Lola Wind Tunnel are now inviting offers. To reach out and learn more, please follow this link.

Lola wind tunnel specification

Maximum model scale: Typically 50% (for open wheel models)

Maximum wind speed: 65m/sec (145 mph)

Maximum rolling road speed: 80m/sec (180 mph)

Turbulent intensity: Less than 0.08%

Wind Temperature: Automatically controlled to 20°C (68°F)

Wind temperature stability: 1 °C during test

Rolling road temperature: 14 °C (nominally)

Test Section dimensions: 2.7m wide x 2.47m high

Diffuser configuration: 7:1 contraction ratio

Main fan motor power: 650KW (872 bhp)

Fan configuration: 5-blade carbon composite

Overhead Balance: 6-component with accuracy greater than 0.04% of range

Model attitude control: Pitch, heave, roll, yaw, wheel steering

Pressure scanning system: Up to 192 sensors

Rolling road dimensions: 2.0m wide x 4.0m long

Maximum model elevation: 600mm above rolling road surface

Motion envelope: ± 5 degrees yaw, ± 3 degrees roll and pitch

Rolling road yaw angle: ± 10 degrees

Software: Cosworth Diablo (with EtherCat interface)

No comments yet